Discover motor performance, without mechanical sensors. The 438-II can help troubleshoot power quality problems in three-phase and single-phase power distribution systems, while giving you the mechanical and electrical information you need to effectively evaluate motor performance. NEW Firmware now supports measurements on variable frequency drives.

Discover motor performance, without mechanical sensors. The 438-II can help troubleshoot power quality problems in three-phase and single-phase power distribution systems, while giving you the mechanical and electrical information you need to effectively evaluate motor performance. NEW Firmware now supports measurements on variable frequency drives.

Discontinued!

This product has been discontinued and is no longer available.

There is no direct replacement, however we recommend the:

Not what you're looking for? Let’s do a search and help you find what you need.

Features

The New Parameters That Can Be Analyzed in Addition To The Power Quality Measurements Are:

Applications

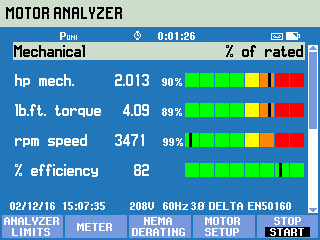

Calculates the amount of rotational force (displayed in lb.ft or Nm) developed by a motor and transmitted to a driven mechanical load. The motor torque is the single most critical variable that characterizes the instantaneous mechanical performance of rotating equipment driven by electric motors.

Provides the instantaneous motor shaft rotational speed. Combined with the motor torque, motor speed provides a snapshot of the mechanical performance of rotating equipment driven by electric motors.

Measures the actual mechanical power (displayed in hp or kW) produced by motors and provides a direct link to overloading conditions without simply basing it on the motor current.

Shows the effectiveness of each motor within a machine, assembly line, plant, and/or facility in converting electric power to useful mechanical work. By properly aggregating the efficiencies of a population of motors the total (aggregate) efficiency can be estimated. Comparisons to expected motor efficiencies at observed operating conditions can help quantify the cost associated with motor energy inefficiency.

Using proprietary algorithms, the Fluke 438-II Power Quality and Motor Analyzer uses three phase current and voltage waveforms to calculate motor torque, speed, load and efficiency at a 1 second update rate. The motor air gap field, as observed via the voltage/current waveforms, provides the basis for the measurements. Mechanical sensors and intrusive no-load motor testing is not required, making it faster than ever to analyze overall electric motor performance.

Simply hookup the voltage measurement leads and flexible current probes to the service supplying the motor.

Input details of the motor from the rating plate including rated power, rated speed and motor type from either NEMA or IEC classifications.

Note: Measurement units can be set to local requirements hp/kW, lb ft/Nm etc.

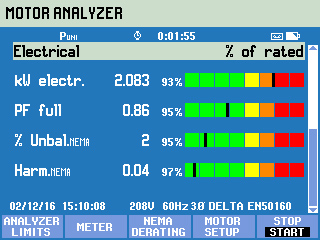

The Fluke 438-II provides a complete breakdown of electrical parameters. Prior to beginning motor analysis, it's recommended to make base line power quality measurements to assess the state of harmonics and unbalance on the electrical service output as these two properties can have a serious negative impact, on motor performance.

When in Motor Analysis mode, results are summarized for electrical performance, mechanical performance and derating (according to NEMA recommendations).

The easy to understand four-level color severity scale indicates motor performance in relation to the recommended electrical parameter levels including rated power, power factor, unbalance and harmonics.

For mechanical power you can instantly view the mechanical output power along with motor torque and speed. The mechanical output power is instantly compared with electrical power to provide you with live efficiency measurements. With this feature you can easily measure machine performance during each operation cycle.

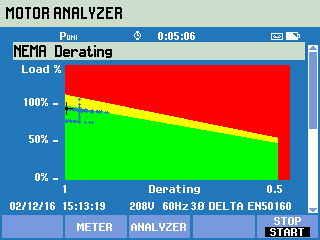

The NEMA derating screen is updated as the load and the electrical conditions change, and each new measurement is plotted on the tolerance graph as a "+". In this example we can see that motor is within tolerance but is close to the service factor. This indicates that there may be a need for power quality mitigation, motor maintenance or some other performance improving adjustment. By frequently performing these tests over time, known benchmarks and performance trends can be created, enabling informed maintenance investment decisions.

Infrared cameras, also called thermal imagers, are useful for troubleshooting motor problems as well as for monitoring motor condition for preventative maintenance in power generation, manufacturing and commercial plants. Thermal images of motors reveal their operating condition as indicated by surface temperature. Such condition monitoring is important as a way to avert many unexpected motor malfunctions in systems that are critical to manufacturing. The onset of motor failures can often be detected by a variety of techniques, including vibration, ultrasound and thermal imaging.

In this article, we cover why use thermal imaging and what to scan, as well as some notes on what to look for, including shaft misalignment.

Read the Article

| Motor Type | 3 Phase Asynchrononous (Induction) |

| Power Source | Variable Frequency Drive |

| Motor Frequency Range | 40 to 70 Hz |

| Over/Under Voltage from Nominal V/f Curve(%) | -15 to 15% |

| Carrier Frequency Range | 2.5 to 20kHz |

| Inverter Type | VSI Only (Voltage Controlled) |

| Control Method | V/f Control Open Loop Vector Closed Loop Vector Drives with Encoders |

| Frequency | 40 to 70Hz |

| Inverter Type | CSI (Current Source Inverter) |

| Motors Type | Non-Synchronous (DC, Stepper, Permanent Magnet, etc.) |

| Motor Frequency | <40 and >70Hz |

Fluke engineers have delivered an innovative mobile platform and tool that helps solve everyday problems, allowing you to instantly document measurements, retrieve historical data, and share live measurements with your team. All handled by the Android™ or iOS smart phone you already carry.

Fluke Connect with ShareLive™ video call is the only wireless measurement system that lets you stay in contact with your entire team without leaving the field. The Fluke Connect mobile app is works with over 20 different Fluke products - the largest suite of connected test tools in the world.

Make the best decisions faster than ever before by viewing temperature, mechanical, electrical and vibration measurements for each equipment asset in one place. Get started saving time and increasing your productivity.

Click on a category to view a selection of compatible accessories with the Fluke 438-II, Power Quality & Motor Analyzer, without FC WiFi SD Card.

| Motor Type | 3 Phase Asynchrononous (Induction) |

| Power Source | Variable Frequency Drive |

| Motor Frequency Range | 40 to 70 Hz |

| Over/Under Voltage from Nominal V/f Curve(%) | -15 to 15% |

| Carrier Frequency Range | 2.5 to 20kHz |

| Inverter Type | VSI Only (Voltage Controlled) |

| Control Method | V/f Control Open Loop Vector Closed Loop Vector Drives with Encoders |

| Frequency | 40 to 70Hz |

| Inverter Type | CSI (Current Source Inverter) |

| Motors Type | Non-Synchronous (DC, Stepper, Permanent Magnet, etc.) |

| Motor Frequency | <40 and >70Hz |

Fluke engineers have delivered an innovative mobile platform and tool that helps solve everyday problems, allowing you to instantly document measurements, retrieve historical data, and share live measurements with your team. All handled by the Android™ or iOS smart phone you already carry.

Fluke Connect with ShareLive™ video call is the only wireless measurement system that lets you stay in contact with your entire team without leaving the field. The Fluke Connect mobile app is works with over 20 different Fluke products - the largest suite of connected test tools in the world.

Make the best decisions faster than ever before by viewing temperature, mechanical, electrical and vibration measurements for each equipment asset in one place. Get started saving time and increasing your productivity.

Click on a category to view a selection of compatible accessories with the Fluke 438-II, Power Quality & Motor Analyzer, without FC WiFi SD Card.